03

2025

-

03

A the praise of customers!

Author:

01 SIBUR team went to Huilong Plastics Machine to accept the equipment

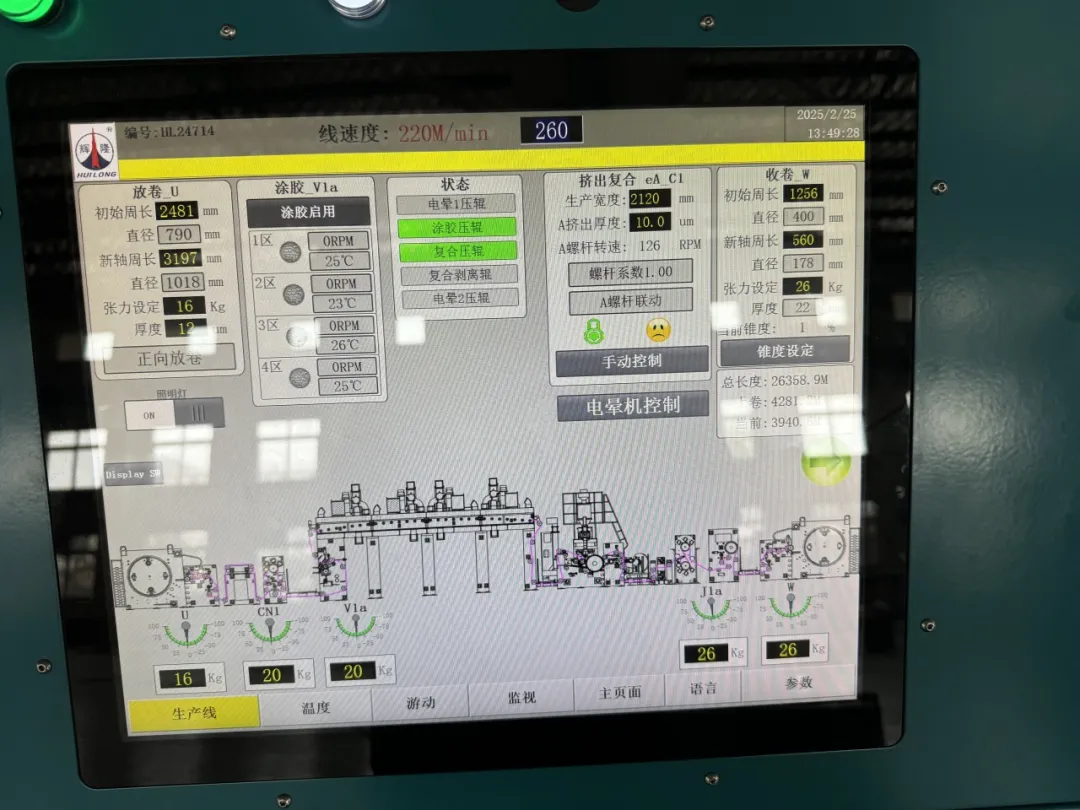

Recently, a team of 10 people (project manager, electrical engineer, technical engineer, production engineer, film inspection engineer, etc.) from SIBUR company in Russia

As the most rigorous acceptance in the history of Huilong Plastics, our customer prepared a 2-week period that started with the main configuration of the equipment, mechanical performance testing, no-load noise testing, followed by a one-week trial production of the product. During the entire acceptance period, a total of more than 500,000 meters of qualified pre-coated film products were produced.

Even in the case of long-term high-load operation, the equipment still performs excellently, and always maintains a stable production state and product quality, such efficient and high-quality equipment has won the high recognition of the SIBUR team!

02 SIBUR CORPORATION

SIBUR is a leading petrochemical company in Russia and Eastern Europe, one of the fastest growing petrochemical companies in the world, and ranks among the top three in the world in the EBITDA earnings index. The company is the second largest producer of synthetic rubber in Europe.

SIBUR covers the entire production chain from natural gas processing to the production of monomers, plastics, synthetic rubber and plastics, which are widely used in the fields of tires, mechanical rubber products, cables and footwear.

03 The core technology of Huilong Plastic Machinery helps customers to produce efficiently

The acceptance work of Huilong Plastics Machinery has been highly appreciated and recognized by SIBUR Company; They said that the introduction of a new generation of "pre-coated film extrusion composite production line" of Huilong Plastics Machinery will vigorously promote the development of downstream products and fill the gap of pre-coated film products in the Russian market.

The new generation of pre-coated film extrusion composite production line breaks the traditional design and manufacturing concept, pays more attention to EHS safety and industrial design, and ensures the safety of operation in an all-round way, while the operation is also more humane!

The new generation of "Pre-coated Film Extrusion Composite Line" equipment (Model: ECX2300/100/300/SHA) purchased by SIBUR Company adopts the following core technologies of Huilong Plastics:

Chaos Mixing Technique

(Invention Patent No.: CN92114886.0)

Using the special chaotic mixing technology screw of Huilong Plastics Machine, acid and corrosion resistance, excellent mixing performance and dispersion plasticizing effect, these layered structures are continuously folded during processing, so as to improve the internal energy of the melt.

Here are the advantages of Chaos Mixing Technology:

1) Lower viscosity, less resistance, reduce extruder energy consumption (compared with similar products at home and abroad, extruder screw power saves about 40% of electrical energy);

2) High melting efficiency (low speed start, low melting resin temperature, 10~20 °C lower than similar at home and abroad);

3) High peel strength.

Patent certificate

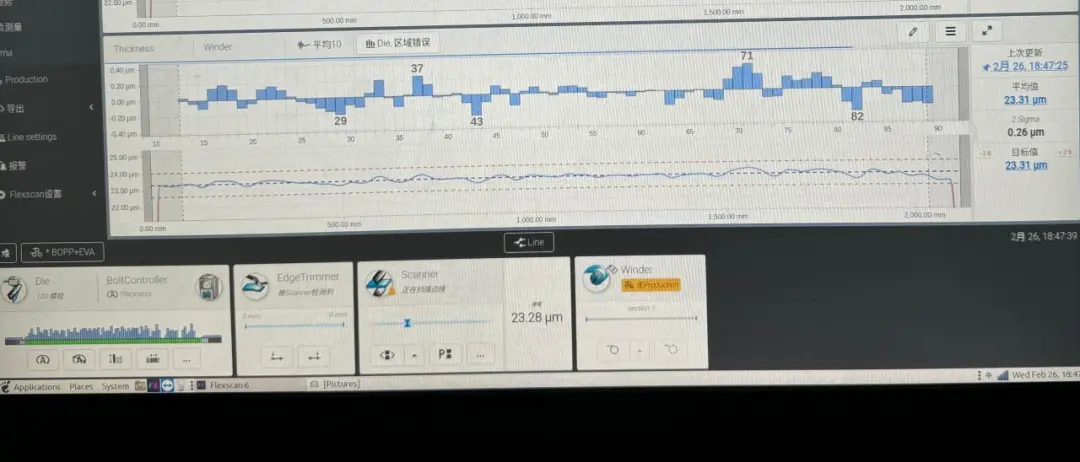

MBL ™ Traveling Autodie with Compensation

Equipped with a Scantech thickness gauge

MBL™ swimming automatic die head with compensation ensures the deviation of coating thickness, and then through the swimming compensation function, the uneven line of winding is compensated by the swimming of the extrusion layer, which solves the problem of unevenness on the surface of the coil in an all-round way, without the traditional "tendon" phenomenon.

Here are the advantages of MBL™ Traveling Autodie with Compensation:

1) Multi-dimensional superposition control system, less deviation of composite film thickness, smooth roll surface, no "bursting" phenomenon.

2) After starting the swimming compensation, the cutting width is not increased, and the loss of edge material is small.

3) The material has a wide range of applications, and both coated grade and non-coated blended resins are applicable.

It can realize the blending of coating grade resin + non-coating grade resin + masterbatch + filler;

Live effects

4) Using servo control, the swimming range and swimming time can be set separately.

5) Provide a three-year warranty.

Product Effects

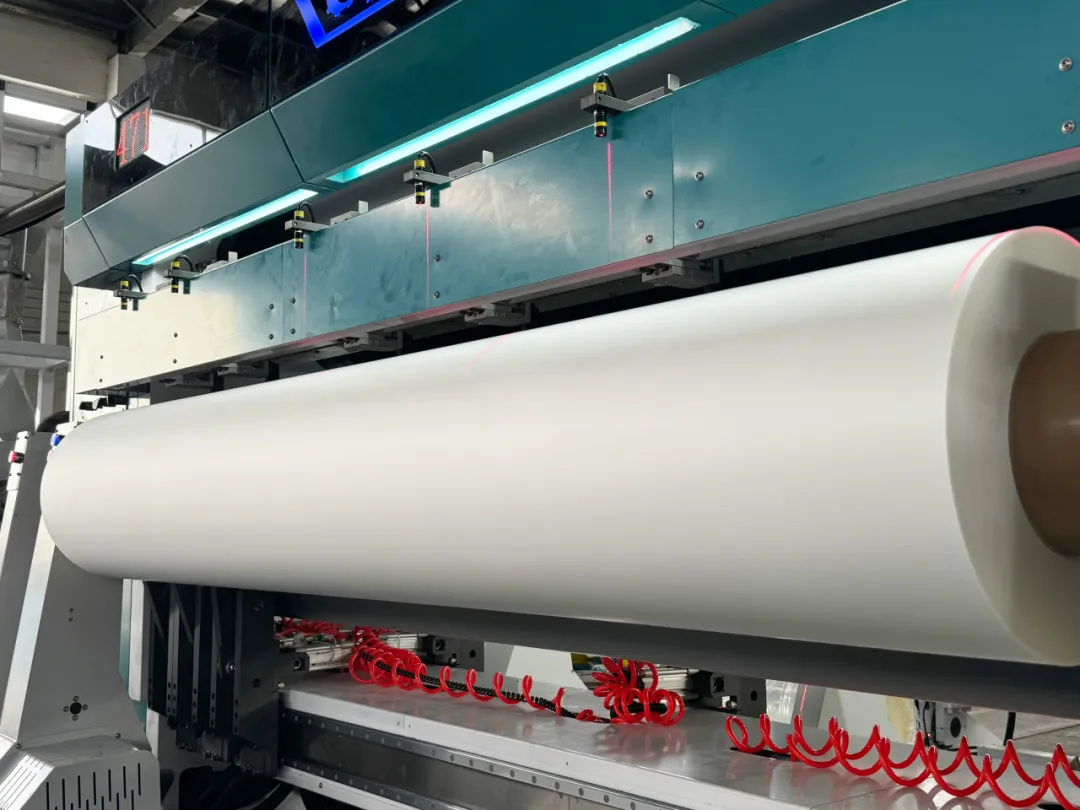

The products produced on our site are rewound by the slitting machine synchronously, and the overall structure is more compact, which highlights the flatness and smoothness of the surface of the coil, even more flat than the original film BOPP, and the rewinding coil presents a better flatness and texture!

Matte film

Light film

Jiangmen Huilong Plastic Machinery Co., Ltd. is a national high-tech enterprise specializing in the development and sales of high-grade extrusion composite production lines. Our company will continue to uphold the concept of environmental protection, professionalism and service, continue to create value for customers, continuously improve product quality and service level, provide customers with more high-quality and efficient packaging solutions, and jointly promote the development and progress of the industry!

Thanks again to SIBUR for their support and trust in Huilong Plastics Machine. We look forward to working with you in the future! Provide innovative solutions to more customers and jointly promote the development of the industry.

Huilong Plastics Machinery warmly welcomes all new and old customers to visit and guide, and work together for cooperation and exchange!

Related News

undefined