NEWS

19

2018

-

06

AMCOR PURCHASED 11 EXTRUSION LAMINATING AMCHINE FROM JIANGMEN HUILONG

Author:

In 2003, Huilong got first cooperation with Alcan Flexible Chengdu(now known as Amcor Chengdu). Till 2014, Amcor has repeatedly purchased 11 extrusion laminating machine from Huilong.In 2014, world's leader in flexible packaging--- Amcor, has purchased three tandem co-extrusion laminating machine and all are successfully accepted to be installed in Huizhou,China, Thailand and Indonesia.

The reason why Amcor Flexibles repeatedly purchased Huilong's extrusion laminating machine is that Huilong possesses unique paptented technology of Chaotic Mixing Low Energy Consumption Extruder with features of:

1) Excellent plasticization in extrusion; 2) High laminating peel strength; 3) Remarkable energy saving in extruder.

Detail data is as followed:

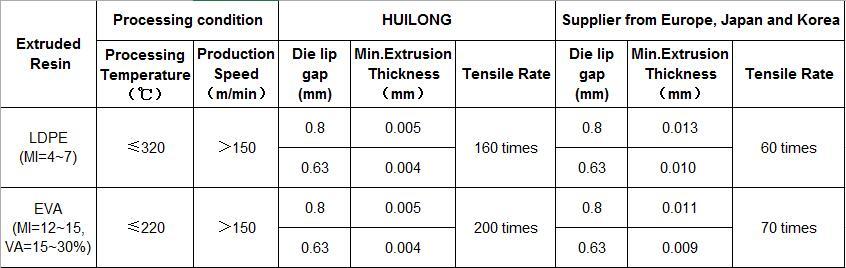

1. Plasticization comparision in extrusion:

Comparision list between Chaotic Mixing Low Energy Consumption Extruder and other international suppliers':

Note:

① The above data is compared under the same processing condition and taken from product summary in other suppliers.

② Maximum tensile rate of Hulong's first generation Chaotic Mixing Low Energy Consumption Extruder is 120 times.

Decisive factor of the tensile rate is chaotic plasticization in extruder. If plasticization of extruder is excellent,there will be low in viscosity, good in ductility and with high tensile rate.On the contrary, if plasticization of extruder is bad, there will be high in viscosity, bad in ductility and with low tensile rate.Also,there will be white crystal point and yellow and black spot due to over-aged in high temperature. There will be stretching fracture in extruded layer and unstable waving on the two edges.

Indicated as per retrieve literature, the second generation Chaotic Mixing Low Energy Consumption Extruder is with remarkable performance with highest tensile rate(200 times) among the world and with thinnest extrusion thickness(0.003mm). It's unique extruder around the world.

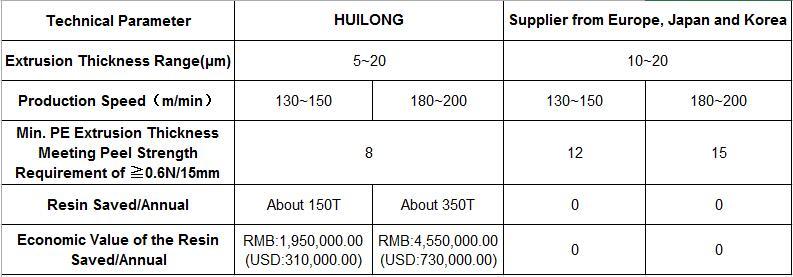

2. High laminating bond strength comparison

Product structure of flexible packaging: BOPP15μm/LDPE/VM-BOPP15μm

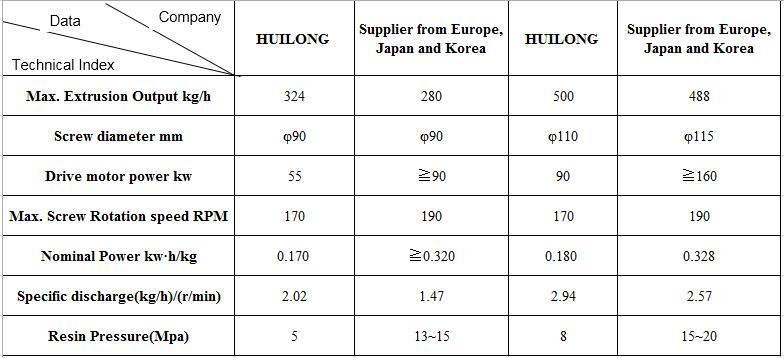

3. Energy saving comparison in extruder (China national standard (JB/T 8061-2011) is 0.32 kWh/kg)

Comparison list of drive power and technical index between Huilong and other suppliers:

Note: Above maximum extrusion output is when extruding LDPE and data is taken from product summary in other suppliers.

3 sets of Huilong tandem co-extrusion laminating machine ordered this time has used Huilong new technology of Amlong Extrusion thickness(MD) controlling system, DC bus drive and distributed bus-mastering contol system. Technician coming for acceptance from Amcor Huizhou, Thailand and Indonesia are all very pleased and appreciated to it. Huilong is worth the name of pioneer and leader in extrusion laminating machine. In the meantime,wish Huilongcontinously have new technology and new achievement to create more value for customer.

Huilong

Related News